Direct-to-Film (DTF) printing is revolutionizing the world of custom printing, especially for businesses looking to create high-quality, cost-effective designs on apparel and other textiles. If you’re new to this technique, it can seem overwhelming at first, but with the right tools, equipment, and knowledge, you can dive into this space and create vibrant, durable prints with ease. In this beginner’s guide, we will walk you through the essential steps of starting with DTF printing, from understanding the basics to picking the right equipment, materials, and scaling your business.

What is Direct-to-Film (DTF) Printing?

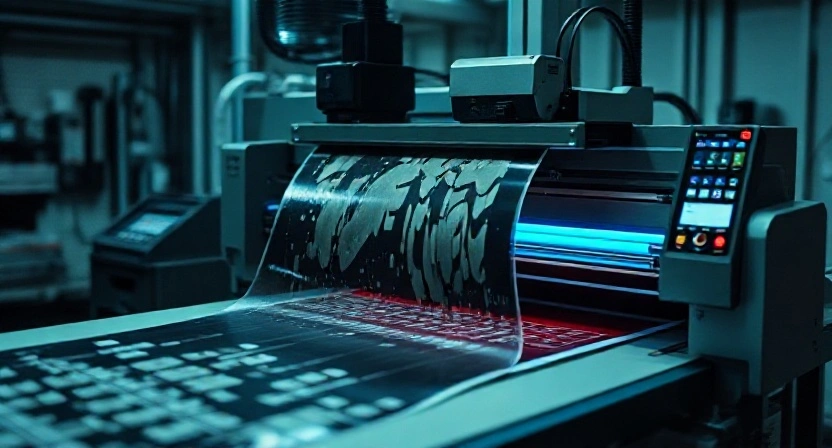

At its core, DTF printing involves transferring digital images onto film, which is then used to create custom prints on various types of fabric. Unlike traditional methods like screen printing, DTF printing offers flexibility, vivid colors, and quick turnarounds for both small and large runs.

What sets DTF apart from other printing methods, such as Direct-to-Garment (DTG) or screen printing, is that it allows for better print durability and color reproduction on a wider range of materials, including cotton, polyester, and blends. While DTG printing requires direct interaction with fabric, DTF uses a transfer process, which makes it perfect for printing on a variety of surfaces that may not be suitable for other printing methods.

Why Choose DTF Printing for Your Business?

For businesses, especially those just starting, DTF printing offers numerous advantages. One of the key benefits is cost-effectiveness. Compared to screen printing, DTF printing does not require expensive setup costs, and it’s perfect for both short and long runs. You don’t need large-scale infrastructure, and you can print as few or as many items as needed. This makes it an ideal choice for custom apparel businesses, promotional product designers, and even personalizing merchandise.

Additionally, DTF prints have excellent durability. The ink bonds well to fabric, providing a long-lasting finish that resists fading, cracking, or peeling, even after numerous washes. Another perk is the ability to print complex, multi-colored designs with no limits on the number of colors, unlike screen printing, which requires separate screens for each color.

Essential Equipment for DTF Printing

To get started with DTF printing, there are a few essential pieces of equipment you’ll need. Let’s break it down:

- DTF Printer: The most critical component of your setup. While there are various models available, one to consider is the Prestige R2 DTF printer, known for its consistency, reliability, and quality prints. It supports high-resolution printing on transfer films and ensures accurate color reproduction, which is crucial for professional-grade designs.

- Heat Press: A heat press machine is necessary for transferring the printed design from the transfer film to the fabric. Look for a machine that provides even heat and pressure distribution, as this will ensure that your prints last longer and adhere properly.

- Transfer Film: This is the material onto which the design is printed before being transferred to the fabric. It’s important to choose the right type of film for your printer and material to ensure crisp, vibrant prints.

- DTF Inks and Powders: The inks used in DTF printing are designed to bond with the transfer film and fabric. You’ll also need a powder that helps the ink adhere during the transfer process. Both the ink and powder must be compatible with the printer you’re using to ensure the best results.

- Curing Oven: Some businesses prefer to use a curing oven to cure the ink and powder after printing, ensuring that the design is fully bonded to the film before being transferred.

While these may seem like a significant investment upfront, they are essential to producing high-quality DTF prints that will set your business apart.

How DTF Printing Works: A Step-by-Step Guide

The DTF printing process is straightforward once you’re familiar with each step. Here’s a breakdown of the process:

Step 1: Preparing the Design

Before printing, you’ll need to create or acquire your design. Most DTF printers work best with high-resolution files, such as PNG or TIFF formats, to ensure that every detail is captured. Use design software like Adobe Illustrator or Photoshop to create your artwork, ensuring that the file is set up correctly for printing.

Step 2: Printing on the Transfer Film

Once your design is ready, the next step is to print it onto the transfer film using your DTF printer. The printer will apply the inks in the correct colors, creating a vibrant image on the film. Keep in mind that DTF printing works best when the design is printed in reverse, as the film will be transferred to the fabric in a mirrored format.

Step 3: Applying the Powder

After printing, the design on the transfer film needs to be coated with a special adhesive powder. This step helps ensure that the inks bond to the fabric during the heat transfer process. The powder is applied manually or through an automatic process, depending on the equipment.

Step 4: Curing the Powder

Once the powder is applied, the film must be cured to ensure the powder adheres to the ink. You can use a curing oven or a flash dryer to heat the powder, which allows it to melt and bond with the design, creating a stable base for transfer.

Step 5: Heat Pressing onto Fabric

Finally, the transfer film with the cured design is placed onto the fabric and pressed using a heat press machine. The high heat and pressure allow the design to transfer from the film to the fabric, bonding it securely.

Choosing the Right Materials for DTF Printing

Not all materials are suitable for DTF printing, so it’s essential to choose the right fabrics. DTF printing works best on cotton, polyester, and cotton-polyester blends. The texture and weight of the fabric can also impact the final result, so make sure to test different materials before offering them to customers.

Additionally, selecting high-quality transfer films and inks is critical. Premium inks and films result in sharper, more vibrant designs that stand the test of time, ensuring customer satisfaction.

Common Mistakes to Avoid

While DTF printing is an accessible process, beginners often make mistakes. Here are a few things to watch out for:

- Incorrect Heat Settings: The temperature and pressure of the heat press must be carefully monitored. Too much heat can cause the fabric to burn, while too little can lead to poor adhesion.

- Poor Quality Transfers: Not all transfer films or inks are created equal. Using low-quality materials can result in faded or blurred prints.

- Underestimating Print Size: Ensure your designs are the right size for the apparel you’re printing on. Misaligning designs can lead to wasted material and poor print results.

How to Price Your DTF Prints for Profit

Pricing your custom prints is crucial for your business’s profitability. Consider factors like material costs, labor, and overhead expenses when setting prices. It’s important to balance competitive pricing with profitability, especially when competing with larger companies. Offering discounts for bulk orders can also help increase sales without compromising on margins.

Marketing Your DTF Printing Business

Once you have your printing process down, it’s time to market your products. Build a strong online presence through social media platforms like Instagram, Facebook, and Pinterest. These are great channels to showcase your work and reach potential customers. Additionally, setting up an e-commerce store can help you sell your custom apparel directly to consumers.

Scaling Your DTF Printing Business

As your business grows, you may want to scale up. This could mean investing in additional printers, hiring staff, or expanding your product offerings. You can also diversify by offering other products like mugs, tote bags, or hats. Always stay updated on the latest advancements in DTF printing to ensure your business remains competitive.

Conclusion

Getting started with DTF printing is an exciting journey that opens up new opportunities for businesses. From understanding the process and picking the right equipment like the Prestige R2 DTF printer to learning how to market your products, there’s a lot to consider. But with careful planning, quality materials, and a focus on customer satisfaction, you can build a successful printing business that stands out in the custom apparel industry.

Leave a comment